Trump’s tariffs have meant a boom in business for one Pennsylvania-based toy manufacturer

In Hatfield, Pennsylvania, The Rodon Group stands out as a rare gem in the manufacturing industry. This privately held plastics injection molding company is one of the few in the US that is dedicated to producing toys alongside other plastic parts. With a production capacity of billions of plastic parts annually, The Rodon Group is known for manufacturing a wide range of products, including window parts, beverage caps, swabs for COVID-19 tests, and the iconic K’nex toy sets.

Michael Araten, the President and CEO of The Rodon Group, leads the company that his family founded in 1956. Amidst the uncertainty surrounding President Trump’s tariffs, business at The Rodon Group is booming. The demand for their products has surged by nearly 50% since the announcement of tariffs, as consumers scramble to navigate the changing tariff landscape.

The recent agreement between the US and China, announced in early May, aims to reduce tariffs on both sides. However, ongoing tensions and uncertainties persist, with China accusing the Trump administration of undermining the trade agreement. The US Court of International Trade has also been involved in the tariff saga, blocking and temporarily reinstating the levies imposed by the president.

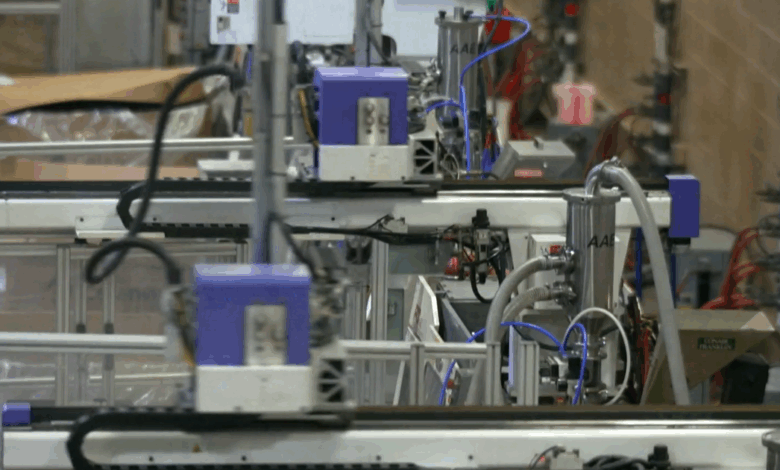

Despite the tariff challenges, The Rodon Group has managed to navigate the chaos by investing in automation to keep the production of K’nex toys in the US. By utilizing robotics technology, the company has been able to compete with offshore manufacturers by reducing labor costs. Araten emphasizes the importance of automation and STEM education in maintaining domestic production, highlighting the need for a skilled workforce in the industry.

While major toymakers like Basic Fun! have faced production halts and price increases due to tariffs, The Rodon Group’s strategic investment in automation has allowed them to stay ahead of the curve. Araten believes that with a focus on automation and workforce development, the US can continue to compete in the global manufacturing market.

As the holiday season approaches, the impact of tariffs on the toy industry remains uncertain. However, companies like The Rodon Group are proving that with innovation and investment, domestic manufacturing can thrive in the face of economic challenges. With a commitment to automation and skilled workforce development, The Rodon Group is setting a precedent for the future of US manufacturing.